Cold Planer - Low Flow | Blue Diamond

BD-LF-CPLNR

limited quantity available

LIMITED TIME FREE SHIPPING!

10% discount applied.

Sale ends May 15, 2024

DETAILS

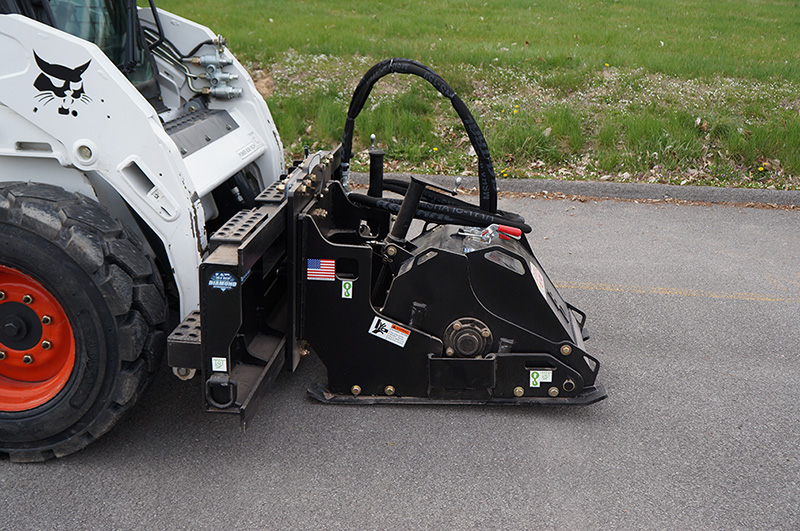

The Blue Diamond® Cold Planer uses the most trusted components in the industry, from the Sauer piston motor, to the Fairfield planetary hub featured in the high-flow models. These high end components, combined with the highly engineered design, makes this one of the most reliable units available for a skid steer attachment.

APPLICATIONS INCLUDE

- Removing asphalt surfaces prior to overlay

- Widening shoulders

- Repairing potholes

- Restoring drainage lines

- Mixing stabilizing agents into base for a more durable repair

| MODEL | NUMBER OF TEETH |

MINIMUM PSI |

MINUMUM FLOW (GPM) |

WEIGHT |

|---|---|---|---|---|

| 12" Low Flow Cold Planer | 30 | 2,000 | 15 GPM | 1,220 LBS |

| 16" Low Flow Cold Planer | 38 | 2,000 | 15 GPM | 1,250 LBS |

features

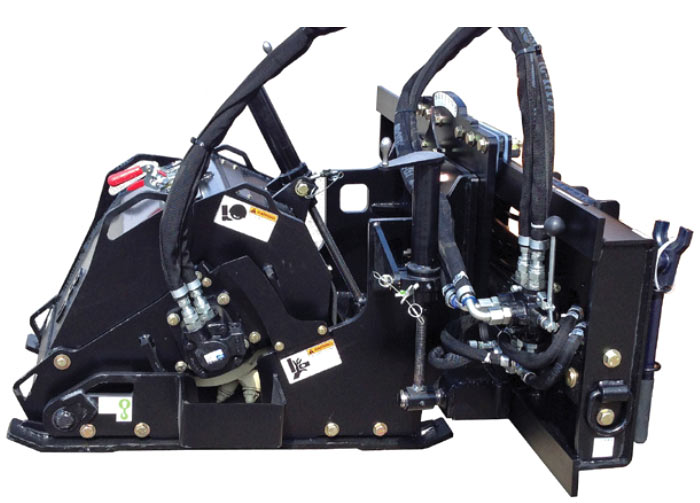

- Manual adjustment controls

- Hydraulic side shift 26"

- Direct Drive

- High drum weight = less vibration

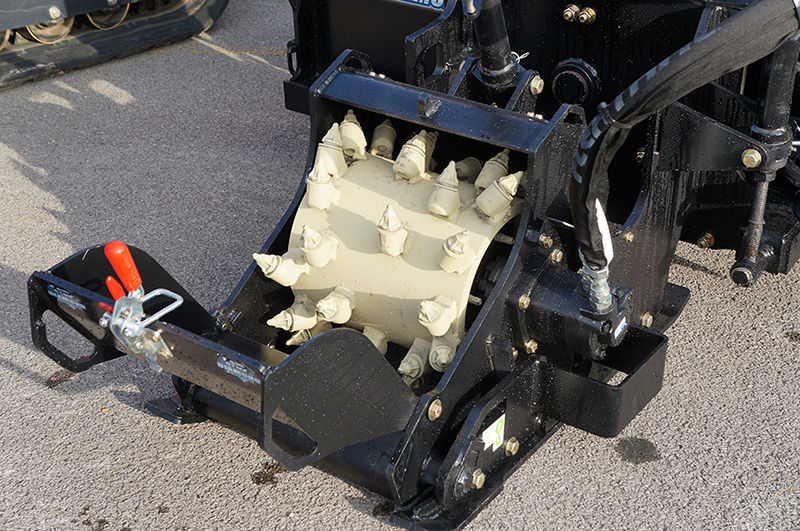

- 5/8” thick drum tube

- Easy access tooth replacement

- Water kit available

- Fine-cut drum available

- 12″-16″ Grinding Widths

- Up to 5″ Cutting Depth

- Tilt +-15 degrees

- Made in the USA

- 1 year warranty

WHAT MAKES OUR COLD PLANER BEST IN CLASS

Side Shift - side shift is a very important feature on a cold planer. Working alongside a curb is an issue faced by most any contractor and can be very frustrating when they are unable to get close enough. Our experience has shown that our cold planer has the most side shift off center in the industry giving you reach you need to get the job done right.

Drum supported on the opposing side from the motor. Our Cold Planer uses a premium load bearing opposite the motor side to support the drum. This is an obvious improvement over most competitors and keeps the machine running smooth and lengthens the life of the attachment.

Skid shoes versus roller wheels. Our experience with roller wheels is that due to the abrasive nature of the material they are in consistently, these last a very short time and then they become a nuisance.

Rocket fin teeth. These teeth turn as they cut and this provides longer tooth life by wearing the tooth consistently and also keeps the tooth from seizing in the holder. Longer tooth life and easier changing saves both time and money. The large access cover also makes tooth changes easier.

You just added this product to your cart